How to Measure the Core Performance of Small Household Appliances?

Understanding the Core Performance Indicators of Small Household Appliances

Evaluating the core performance of small household appliances involves analyzing their functional efficiency, operational stability, user experience, and long-term reliability. For manufacturers like Ningbo Fashida Appliance Technology Co., Ltd., which specializes in developing and producing various small household appliances within China’s established industrial ecosystem in Cixi, these indicators help ensure that products meet market expectations and support brand competitiveness. Core performance measurement begins by defining which parameters reflect the true value of an appliance, such as power output, operational speed, noise generation, temperature control, and durability. By establishing quantifiable benchmarks, manufacturers can assess whether the product achieves consistent performance during actual use. This structured assessment also helps guide design improvements and enhance overall production quality.

Evaluating Power Efficiency and Energy Consumption

Power efficiency is a significant performance factor because it directly influences the long-term operating cost and usability of small household appliances. Devices such as kettles, blenders, heaters, and fans depend on optimized power allocation to achieve their intended function within an acceptable time frame. Ningbo Fashida Appliance Technology Co., Ltd. incorporates standardized testing facilities that simulate real-world usage to evaluate actual energy consumption rates. Through repeated measurement cycles, manufacturers can calculate average power usage, standby energy loss, and other efficiency parameters. Quantitative evaluation of power efficiency ensures that the appliance minimizes unnecessary energy waste while still delivering stable performance. This type of testing supports both environmental requirements and customer expectations for efficient household products.

Assessing Mechanical Performance and Functional Stability

Mechanical performance refers to the operational capability of components such as motors, gears, heating elements, and rotating shafts. For small household appliances, stability during continuous use is an important indicator of durability and reliability. Manufacturers, including Ningbo Fashida Appliance Technology Co., Ltd., conduct repeated functional testing, stress testing, and load simulations to examine whether appliances maintain their operating precision and speed without excessive wear. Mechanical stability can also be evaluated by analyzing vibration patterns, component temperature rise, and mechanical noise output during operation. These indicators help determine whether the appliance can deliver consistent results over extended periods and under different working conditions.

Testing Safety Features and User Protection Mechanisms

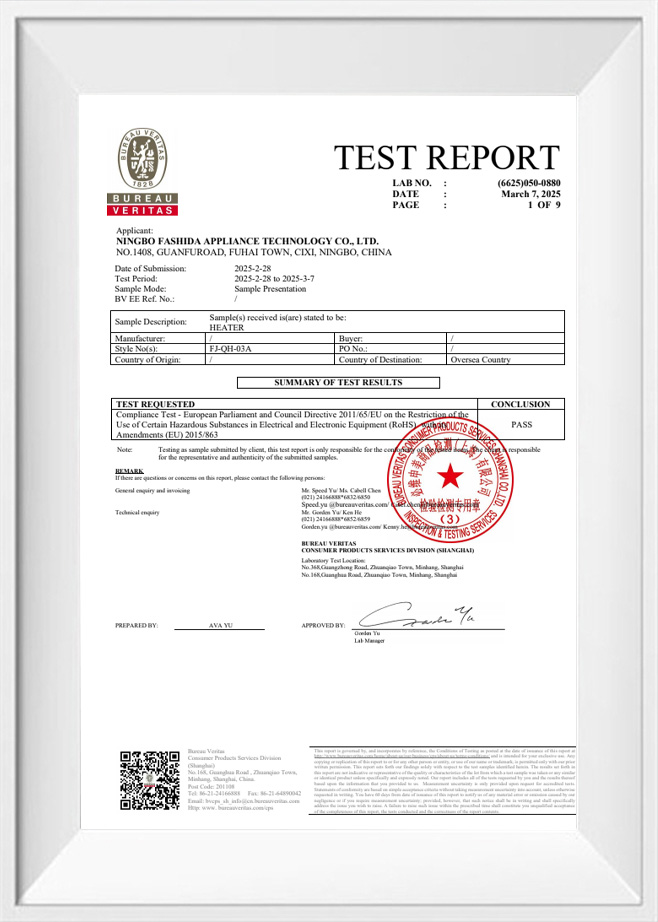

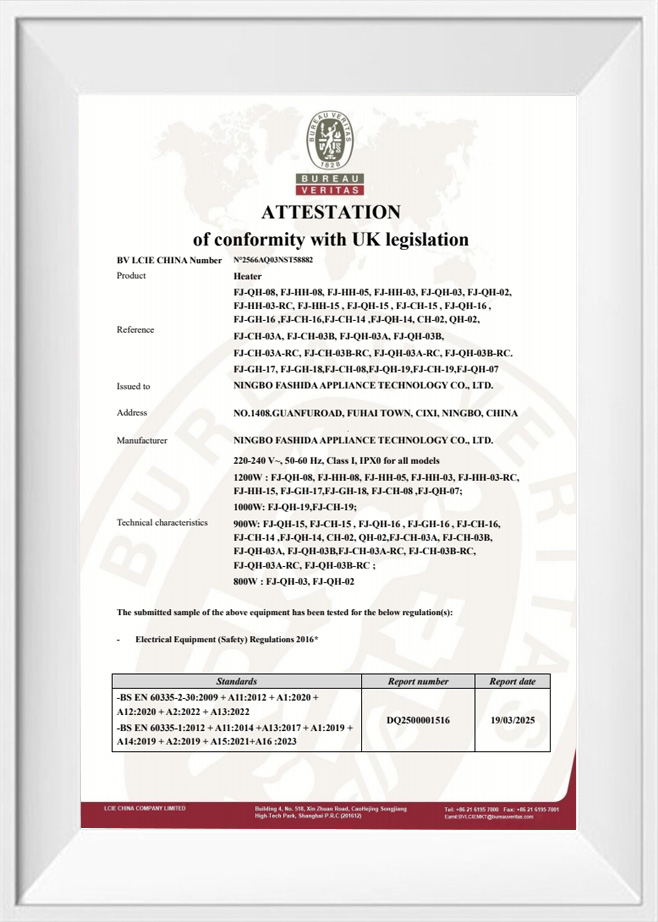

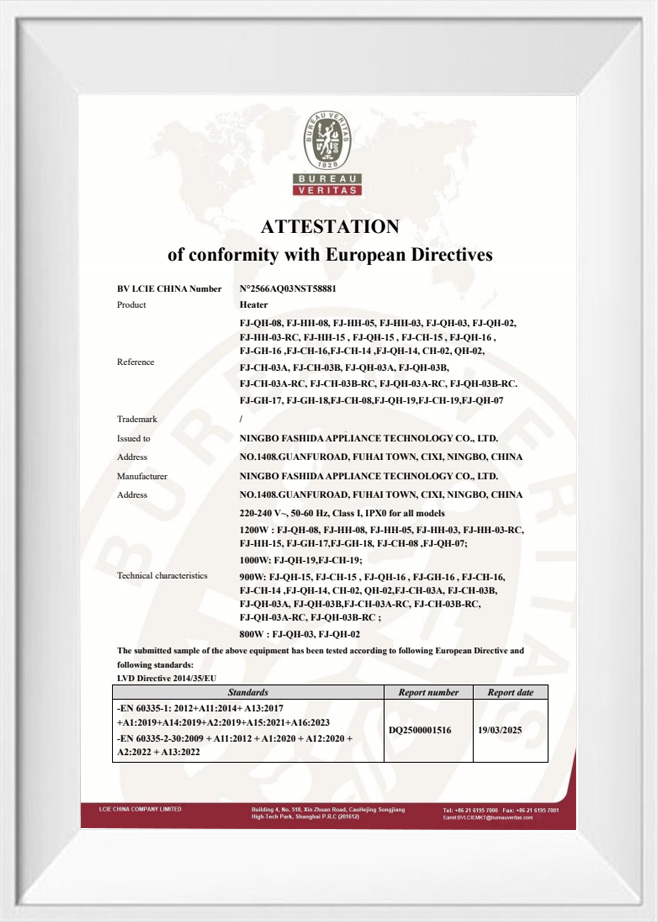

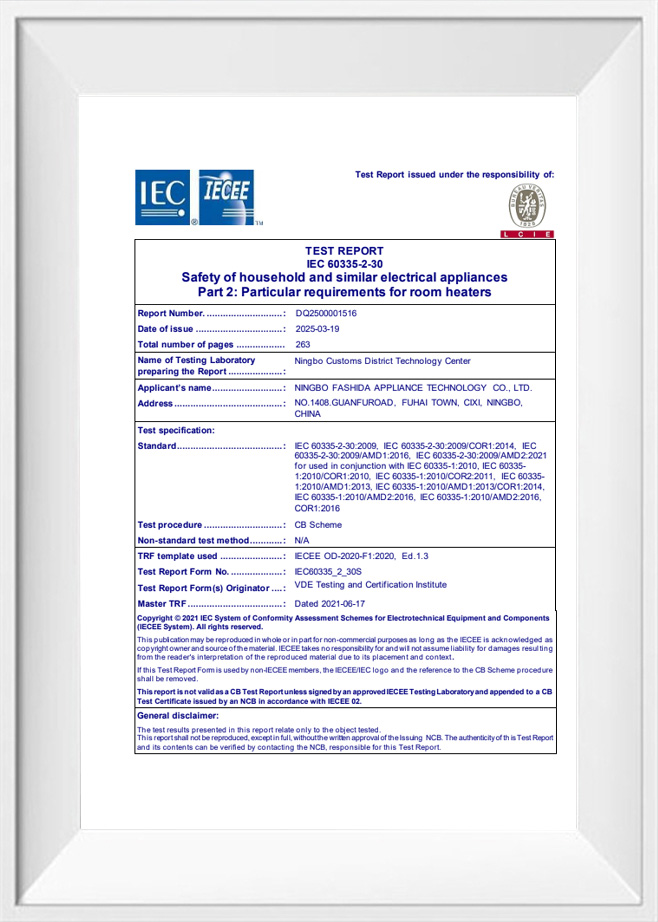

Safety performance is an essential part of evaluating small household appliances, especially those involving electrical components or heating systems. Safety mechanisms may include automatic shutdown, overload protection, insulation quality, temperature limiters, and anti-overheating designs. Ningbo Fashida Appliance Technology Co., Ltd. strictly follows industry standards and applies testing procedures that assess how appliances respond under abnormal conditions. For example, safety performance can be evaluated by simulating electrical overload, measuring insulation resistance, or exposing devices to prolonged high-temperature environments. The goal is to ensure that the appliance minimizes risk during normal and accidental usage. These thorough safety evaluations help manufacturers design appliances that protect users and comply with national and international regulations.

Noise Level Measurement and User Comfort Assessment

Noise measurement is a key performance indicator for appliances with motors, air movement systems, or mechanical transmission components. Customers often prefer appliances that maintain comfortable noise levels during operation, making noise control an important part of product development. Manufacturers typically use a controlled acoustic environment to measure sound pressure levels under different operational modes. Ningbo Fashida Appliance Technology Co., Ltd. incorporates noise testing into its performance evaluation process to determine whether design adjustments—such as improved motor balancing or sound-absorbing materials—are needed. Beyond numerical sound measurements, subjective user comfort testing can provide additional insights into how noise influences long-term user satisfaction.

Durability Testing and Long-Term Reliability Evaluation

Durability testing evaluates whether the appliance maintains consistent function after repeated use over an extended period. Manufacturers simulate real-world usage by running products through long-term operational cycles that mimic daily household routines. Ningbo Fashida Appliance Technology Co., Ltd. integrates durability testing as a standard component of its quality assurance system. Parameters such as material fatigue, wear resistance, heat stability, and component degradation are monitored throughout the testing process. By identifying potential failure points early, manufacturers can refine internal structures, improve material selection, and enhance manufacturing processes. Long-term reliability is especially important for portable appliances and those used frequently in modern households.

Creating Technical Performance Tables for Comparison

Technical tables help manufacturers and users visually compare the performance characteristics of different small household appliances. A well-structured table summarizes important indicators, supports decision-making, and provides clarity in quality control analyses. Below is an example performance evaluation table that could be used in a production environment at Ningbo Fashida Appliance Technology Co., Ltd.

| Performance Category |

Key Indicators |

Testing Methods |

| Power Efficiency |

Energy consumption, operational wattage |

Power meter testing, load simulation |

| Mechanical Stability |

Motor speed, vibration, temperature rise |

Continuous operation test, vibration analysis |

| Safety Features |

Overload protection, insulation, auto-shutdown |

Electrical safety test, simulated fault test |

| Noise Level |

Sound pressure (dB) |

Acoustic room test, multi-mode measurement |

| Durability |

Operational lifespan, component wear |

Long-cycle testing, material fatigue analysis |

Performance Evaluation from a Manufacturing Perspective

From the viewpoint of a manufacturer like Ningbo Fashida Appliance Technology Co., Ltd., measuring core performance supports both product innovation and market competitiveness. Performance assessment not only verifies functional quality but also helps improve production efficiency by identifying potential issues before mass production. Integrating accurate measurement methods into the development cycle allows manufacturers to refine designs, enhance quality control standards, and maintain consistency across product batches. For the competitive small household appliance industry, a systematic performance evaluation approach demonstrates the manufacturer's commitment to dependable engineering, structured testing processes, and reliable product outcomes.

Do Small Household Appliances Affect Indoor Air Quality?

Understanding the Relationship Between Small Household Appliances and Indoor Air Quality

Indoor air quality is influenced by various environmental factors, including ventilation efficiency, indoor activities, and the operation of household appliances. As a professional manufacturer in China’s small appliance industry, Ningbo Fashida Appliance Technology Co., Ltd., headquartered in Cixi, plays a key role in delivering appliances designed for daily household use. Many small appliances, such as heaters, humidifiers, air fryers, electric cookers, and vacuum cleaners, interact with the indoor environment and may influence air quality. Evaluating this relationship helps consumers make informed choices and encourages manufacturers to develop products that support healthy living spaces. Understanding the potential impact of each appliance category requires examining heating behavior, emission characteristics, filtration technologies, and device maintenance requirements.

Heating Appliances and Their Influence on Indoor Air Quality

Heating appliances such as electric heaters, hair dryers, and portable warmers are commonly used in households, especially during seasonal changes. Although these appliances do not directly emit pollutants in most cases, they can affect indoor air quality by increasing air circulation and accelerating dust movement. In addition, when appliances operate at higher temperatures, there is a possibility of minor emissions from heated internal components, especially if dust has accumulated inside the device. Ningbo Fashida Appliance Technology Co., Ltd. focuses on careful material selection and rigorous manufacturing standards to minimize these potential effects. Regular maintenance, proper ventilation, and ensuring appliances remain dust-free can help maintain cleaner indoor air during operation.

Cooking-Related Small Appliances and Particle Emission

Kitchen appliances such as air fryers, electric grills, rice cookers, and induction cooktops can affect indoor air quality because they generate heat, steam, and small particles during food preparation. Particle concentration increases particularly when frying or grilling food. If these devices are used in poorly ventilated spaces, particles may accumulate and influence indoor air quality. Manufacturers like Ningbo Fashida Appliance Technology Co., Ltd. pay attention to heating element stability, housing design, and ventilation structures that help reduce unnecessary emissions. Proper usage, such as operating cooking appliances near exhaust fans or in areas with adequate airflow, can significantly reduce the impact of steam, oil particles, and odors on indoor air.

Humidifiers, Dehumidifiers, and Moisture Regulation

Humidity-related appliances are closely linked to indoor air quality because they directly influence moisture levels in the environment. Humidifiers increase air moisture, and improper maintenance may allow microbial buildup inside the device. When this occurs, airborne particles or odors may enter the room. Dehumidifiers, on the other hand, help lower humidity but require regular cleaning of internal tanks and filters to prevent mold growth. Ningbo Fashida Appliance Technology Co., Ltd. applies strict production standards to ensure that water-contact components use materials designed for safe interaction with moisture. Regular cleaning and the use of clean water can help users maintain balanced humidity levels without compromising indoor air quality.

Vacuum Cleaners and Air Filtration Performance

Vacuum cleaners play a central role in controlling indoor dust concentration, but their influence on air quality depends largely on filtration performance. Devices without effective filters may release fine dust back into the air during operation. Advanced filtration systems such as HEPA filters can effectively capture small particles, helping maintain clean indoor environments. As a manufacturer of small household appliances, Ningbo Fashida Appliance Technology Co., Ltd. pays attention to filtration technology integration, sealing structure optimization, and motor air channel design. The effectiveness of vacuum cleaners in improving indoor air quality is closely linked to proper maintenance of filters, regular cleaning of dust containers, and ensuring that the appliance maintains stable suction performance.

Air Circulation Appliances and Dust Resuspension

Fans, portable air circulators, and bladeless fans do not produce emissions, but they can influence indoor air quality by resuspending settled dust. Air movement redistributes particles, causing temporary increases in airborne dust. While this effect is mostly short-term, it highlights the importance of keeping indoor environments clean. Appliances produced by Ningbo Fashida Appliance Technology Co., Ltd. are designed to optimize airflow patterns while maintaining energy efficiency. Proper placement of air circulation appliances, combined with regular cleaning of blades, grills, or air outputs, can help reduce unwanted dust movement in indoor environments.

Evaluating Air Quality Impact Through Technical Indicators

Manufacturers evaluate the impact of small household appliances on indoor air through standardized testing methods. These tests involve measuring particle concentration, temperature changes, humidity adjustments, and odor levels during operation. Technical indicators help determine whether a product influences indoor air quality and what improvements may be needed during production. Below is an example table summarizing key evaluation parameters.

| Appliance Category |

Potential Air Quality Impact |

Testing Indicators |

| Heating Appliances |

Air circulation, dust disturbance |

Temperature stability, dust concentration levels |

| Cooking Appliances |

Steam, oil particles, odors |

Particle measurement, VOC testing |

| Humidity Appliances |

Moisture imbalance, microbial growth (if unmaintained) |

Humidity variation, microbial analysis |

| Vacuum Cleaners |

Dust filtration effectiveness |

Filter efficiency, dust escape measurement |

| Air Circulators |

Dust redistribution |

Airflow analysis, particle movement tracking |

The Role of Manufacturing Quality in Air Quality Impact

Manufacturing quality plays a significant role in determining whether an appliance affects indoor air. Ningbo Fashida Appliance Technology Co., Ltd. emphasizes precise engineering, stable internal structures, and durable materials to support product reliability and safe operation. The quality of seals, ventilation channels, motors, heating components, and water-contact surfaces determines how appliances interact with the indoor environment. For example, well-designed filtration systems reduce dust escape from vacuum cleaners, and stable heating elements minimize odor release. Manufacturers also perform emission and air quality compatibility tests before products enter mass production. These processes help ensure that appliances operate efficiently while maintaining an environment with acceptable air quality.

User Practices and Maintenance Influence Indoor Air Quality

Apart from manufacturing quality, everyday user habits significantly affect indoor air quality when operating small household appliances. Proper maintenance, timely filter replacement, cleaning of water tanks, and ensuring adequate ventilation can reduce the influence of appliances on indoor air. Even well-designed appliances may affect air quality if they accumulate dust or are used incorrectly. Users can improve indoor air conditions by regularly cleaning devices, following manufacturer guidelines, and placing appliances in well-ventilated areas. Manufacturers like Ningbo Fashida Appliance Technology Co., Ltd. often provide detailed instructions to help users maintain safe and effective appliance operation.

View More

FJ-X01 Bottom Loading Water Dispenser

With consistent cooling and heating capabilities, this water dispenser delivers reliable performance...

View More

FJ-X01 Bottom Loading Water Dispenser

With consistent cooling and heating capabilities, this water dispenser delivers reliable performance...

View More

FJ-X003 Intelligent Heating Water Dispenser

The FJ-X003 Intelligent Heating Water Dispenser combines high efficiency with a user-friendly design...

View More

FJ-X003 Intelligent Heating Water Dispenser

The FJ-X003 Intelligent Heating Water Dispenser combines high efficiency with a user-friendly design...

View More

0Y-001 Tabletop Hot And Cold Water Dispenser

The 0Y-001 tabletop hot and cold water dispenser is made from high-quality, FDA-approved PP polymer,...

View More

0Y-001 Tabletop Hot And Cold Water Dispenser

The 0Y-001 tabletop hot and cold water dispenser is made from high-quality, FDA-approved PP polymer,...

English

English 中文简体

中文简体