Do Small Home Appliance Spare Parts Apply to Both Old and New Models?

The compatibility of spare parts across old and new models of small home appliances depends on multiple factors, including product design evolution, functional upgrades, and safety requirements. In the small appliance industry, many components maintain consistent design patterns for long periods, while others change significantly as brands enhance performance or comply with updated standards. Companies such as NINGBO FASHIDA APPLIANCE TECHNOLOGY CO., LTD., which specializes in heaters, water dispensers, fans, and other household appliances, often balance technological improvement with structural continuity to ensure practical maintenance options for users in global markets.

Influence of Product Design Evolution on Spare Part Fitment

Product design updates play an important role in determining whether spare parts can be shared across versions. When manufacturers revise components such as fan blades, heating elements, pump mechanisms, or electronic control boards, they may modify dimensions, connection interfaces, or materials. These changes can help improve function or energy use but sometimes reduce backward compatibility. In companies with strong R&D capabilities like NINGBO FASHIDA APPLIANCE TECHNOLOGY CO., LTD., design teams aim to integrate enhancements while minimizing disruptions to spare part availability so existing users can maintain their appliances without excessive cost or difficulty.

Standardized Components That Often Remain Compatible

Some spare parts follow industry-standard sizes and specifications, making them compatible with both older and newer appliance models. These may include basic switches, power cords, fastening hardware, water inlet pipes, or certain motor types. Because these components are widely adopted across the appliance industry, manufacturers frequently retain their standardized designs to maintain production efficiency and reduce supply chain complexity. The following table summarizes common spare parts that tend to show broader compatibility across model generations:

| Part Category |

Typical Compatibility |

Reason for Stability |

| Power Cords |

High |

Standard plug types and voltage specifications |

| Switches and Buttons |

Medium to High |

Common mechanical structures used across models |

| Fan Motors (Basic Types) |

Medium |

Consistent rotational needs and mounting designs |

| Water Pipes / Connectors |

High |

Standardized diameters and pressure requirements |

Parts That Frequently Change With New Models

Certain spare parts experience frequent design updates as small home appliances evolve. Components related to control systems, sensors, heating efficiency, and safety improvements often undergo revisions when brands launch new models. This is especially common in heaters and water dispensers, where regulatory compliance and performance stability influence internal structure. For companies like NINGBO FASHIDA APPLIANCE TECHNOLOGY CO., LTD., integrating new safety features or energy-saving adjustments often requires modifying circuit boards, thermostats, or electronic modules. As a result, these modernized parts may not be interchangeable with older versions.

Impact of Manufacturing Strategies on Compatibility

Manufacturers adopt different strategies when balancing innovation and continuity. Some companies follow modular design principles, making spare parts easier to replace or compatible across generations. Others may redesign entire product lines to meet new functional goals, which can limit compatibility. NINGBO FASHIDA APPLIANCE TECHNOLOGY CO., LTD. often incorporates structural consistency in key sections of their appliances, enabling users to maintain their devices with accessible parts while still benefiting from performance enhancements in new models. This approach supports long-term customer trust and reduces waste by allowing older appliances to remain in service.

Considerations for End Users Replacing Spare Parts

Users looking to replace spare parts should verify technical specifications such as size, voltage, wattage, connector type, or mounting method. Even when two parts appear outwardly similar, small differences may affect installation or performance. Appliance manufacturers provide model-specific manuals or online resources that list appropriate spare parts. For brands with strong international presence like NINGBO FASHIDA APPLIANCE TECHNOLOGY CO., LTD., clear guidance helps users in different regions find the correct components. Ensuring accuracy in spare part selection reduces the risk of malfunction and extends the lifespan of the appliance.

Supplier and Distributor Role in Maintaining Compatibility Information

Suppliers and distributors play an important role in ensuring users can identify compatible parts for old and new models. Many maintain databases that link product versions with updated or discontinued components. This support is valuable for global manufacturers whose appliances serve markets with varied maintenance practices. For companies like NINGBO FASHIDA APPLIANCE TECHNOLOGY CO., LTD., collaboration with supply chain partners ensures that spare parts remain accessible, and that compatibility information is communicated accurately across international dealer networks.

Industry Trend Toward Modular and Replaceable Components

In recent years, the small appliance industry has shifted toward modular construction to simplify repairs and reduce electronic waste. Modular designs allow multiple generations of products to share core spare parts, improving sustainability and user convenience. This trend aligns with increasing global expectations for longer-lasting appliances and more transparent spare parts availability. Manufacturers with established R&D capabilities, such as NINGBO FASHIDA APPLIANCE TECHNOLOGY CO., LTD., are positioned to adopt such trends by integrating adaptable components in fans, heaters, and water dispensers, supporting both product longevity and environmental responsibility.

Do the Spare Parts for Small Home Appliances Meet High-Temperature Resistance and Safety Standards?

Industry Requirements for High-Temperature-Resistant Spare Parts

Spare parts for small home appliances must meet specific high-temperature resistance and safety standards to ensure long-term reliability and user protection. Components used in heaters, water dispensers, and fans often operate near heat sources or electrical circuits, making temperature endurance an essential requirement. Manufacturers in major appliance hubs, such as NINGBO FASHIDA APPLIANCE TECHNOLOGY CO., LTD., follow structured production guidelines to ensure their parts can withstand thermal stress under normal and extended use. These industry requirements establish performance expectations that support everyday household operation without compromising functional stability.

Material Selection and Its Impact on Temperature Resistance

High-quality materials are a key determinant in the thermal performance of spare parts. Components such as heating elements, plastic housings, motor casings, and internal wiring are typically exposed to fluctuating temperatures. To meet safety expectations, manufacturers select materials with controlled heat deformation properties and strong insulation capabilities. For example, heat-resistant plastics are utilized for exterior covers on water dispensers, while nickel-chromium alloys are commonly applied in heater elements. A strong R&D base, such as that of NINGBO FASHIDA APPLIANCE TECHNOLOGY CO., LTD., supports continued refinement of materials used in small appliances so they can maintain durability and safety over time.

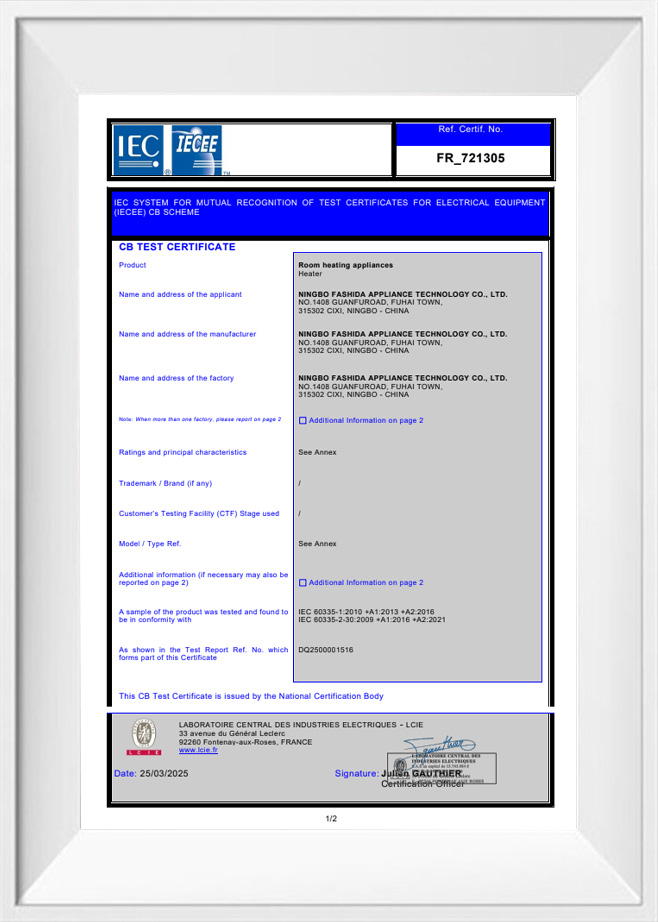

Compliance With Safety Certifications and Testing Procedures

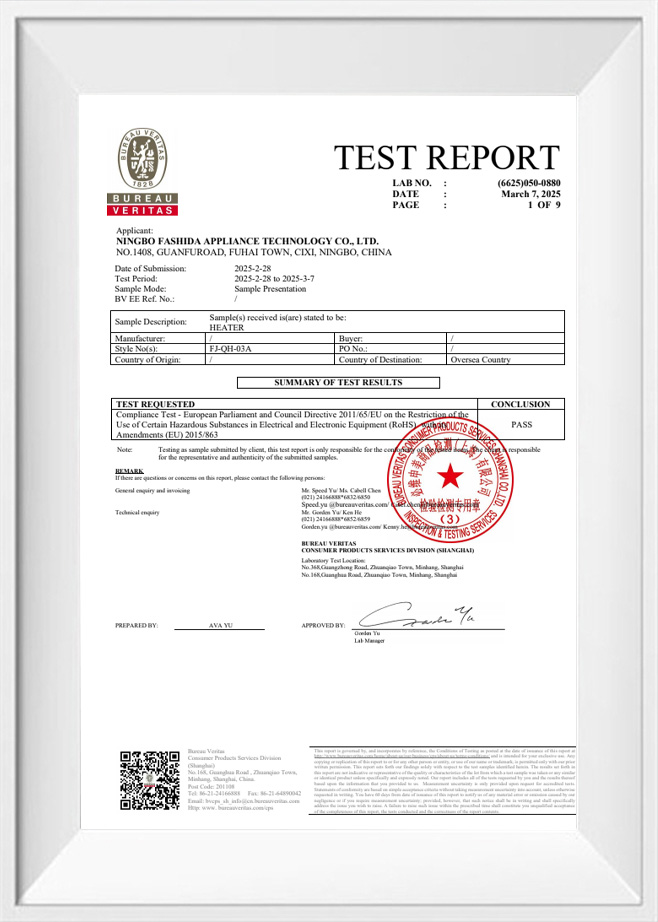

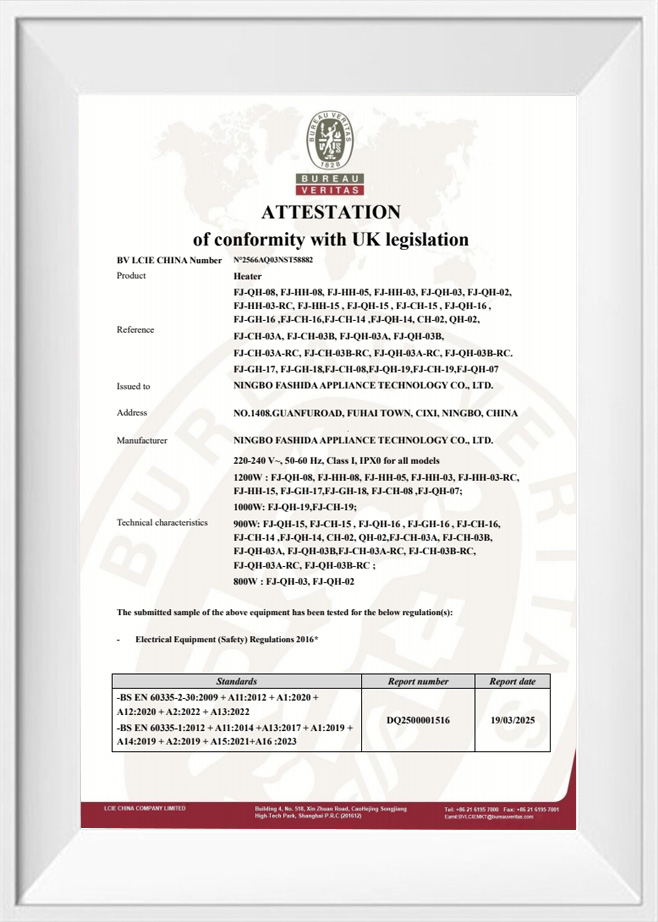

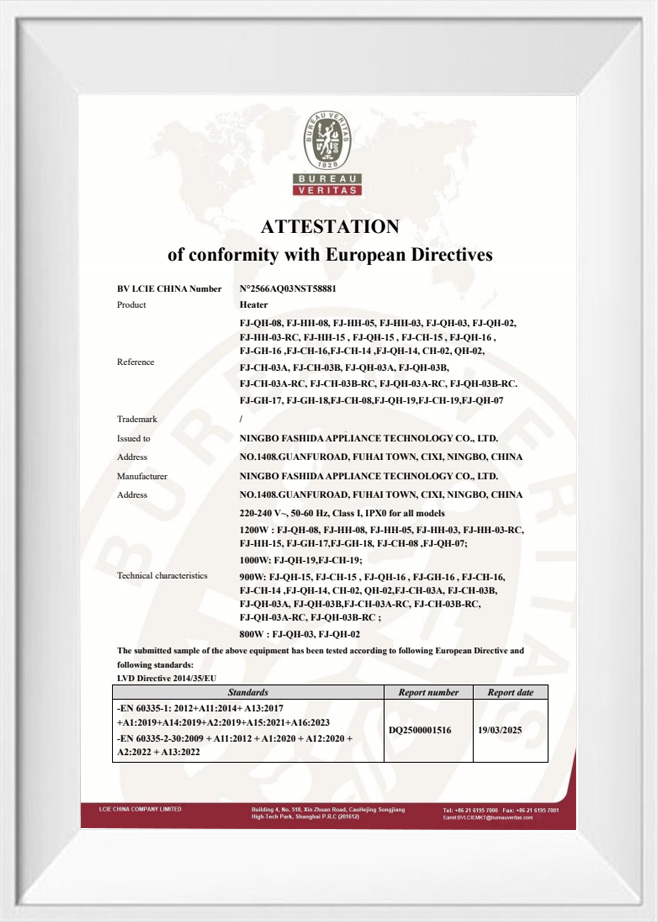

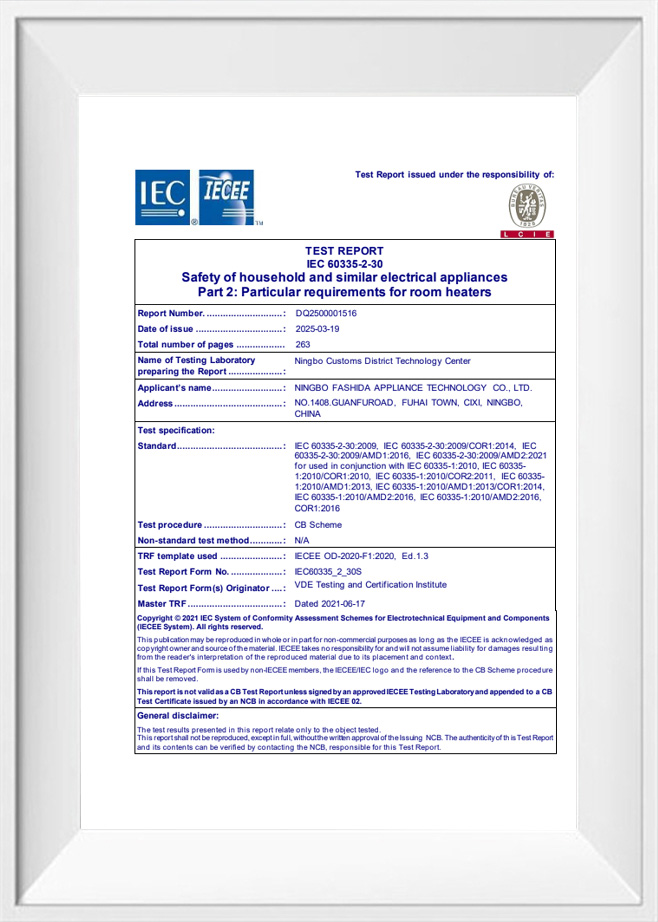

To determine whether spare parts meet the required high-temperature standards, manufacturers perform a combination of internal testing and third-party certification. Safety certifications may include ISO, CE, ETL, or other regional standards that define temperature thresholds, electrical stability, and structural reliability. Testing procedures typically involve thermal exposure cycles, insulation resistance checks, and flame-retardant evaluations. By following these structured tests, companies ensure that parts used in heaters, fans, and water dispensers stay stable during operation. For manufacturers like NINGBO FASHIDA APPLIANCE TECHNOLOGY CO., LTD., compliance demonstrates a consistent approach to global safety requirements and supports confidence among international customers.

Spare Parts Commonly Designed for High-Temperature Environments

Different small appliances require specific spare parts with tailored heat-resistant properties. Heater components undergo the greatest thermal stress, while water dispensers and fans have parts that tolerate moderate temperatures. The table below summarizes typical spare parts and their general high-temperature tolerance characteristics:

| Spare Part |

Typical Appliance Type |

High-Temperature Role |

| Heating Element Coil |

Electric Heaters |

Maintains function at thermal peaks without structural change |

| Heat-Resistant Plastic Housing |

Water Dispensers / Fans |

Prevents deformation and maintains electrical safety |

| Thermal Cutoff Fuse |

Heaters / Water Heaters |

Interrupts power when temperature exceeds defined threshold |

| Insulated Copper Wiring |

All Small Appliances |

Maintains insulation performance during heat cycles |

Role of Thermal Cutoff and Safety Circuits in Appliance Function

To further support safety, many small home appliances integrate thermal cutoff devices and safety circuits that rely on heat-resistant spare parts. These components are designed to automatically disable power if abnormal heating occurs, preventing potential damage or unsafe conditions. Companies like NINGBO FASHIDA APPLIANCE TECHNOLOGY CO., LTD., which produce heaters and water dispensers, incorporate these systems into product design to improve operational safety across global markets. When these spare parts are replaced, maintaining compliance with certified temperature-resistant components is essential to preserve the intended protective functions.

How Manufacturers Ensure Spare Part Safety During Production

During manufacturing, multiple stages of inspection ensure that spare parts meet required thermal endurance levels. Raw materials undergo verification to confirm heat resistance consistency, while semi-finished components are tested under controlled temperature environments. Final inspection involves operational simulation, where parts are inserted into functional appliances to evaluate real-world behavior. For a manufacturer with strong production experience like NINGBO FASHIDA APPLIANCE TECHNOLOGY CO., LTD., these multilayered quality checks support stable performance across product categories and help maintain a dependable reputation in international markets.

Consumer Considerations When Replacing High-Temperature-Related Spare Parts

When consumers replace spare parts in heaters, water dispensers, or fans, it is important to choose components that match original safety standards. Even when third-party spare parts appear similar, differences in heat tolerance or material composition may affect appliance performance. Users should consult product manuals, manufacturer recommendations, or authorized distributors to confirm compatibility. Appliances from established companies like NINGBO FASHIDA APPLIANCE TECHNOLOGY CO., LTD. are often supported by organized spare part systems that help consumers choose compliant replacements and maintain both temperature stability and overall safety.

Industry Trends Toward Higher Thermal Durability and Safer Component Design

As household appliances become more compact and efficient, the demand for advanced heat-resistant components continues to increase. Manufacturers are integrating improved insulation materials, enhanced thermal sensors, and optimized airflow structures to manage heat distribution. These evolving design strategies support safer operation without requiring major changes in user habits. Companies with strong R&D capabilities, such as NINGBO FASHIDA APPLIANCE TECHNOLOGY CO., LTD., contribute to these developments by applying their technological resources to improve spare part design and enhance overall appliance safety in various categories.

View More

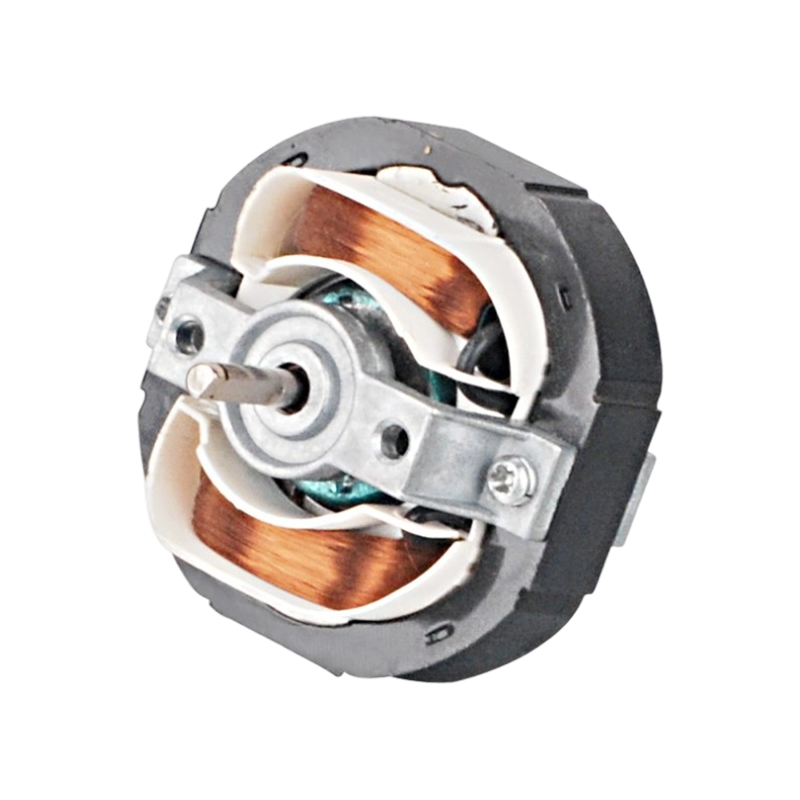

FJD-01 electric motor

This home appliance spare part is designed to work with both 110-127V and 220-240V voltage ranges, m...

View More

FJD-01 electric motor

This home appliance spare part is designed to work with both 110-127V and 220-240V voltage ranges, m...

View More

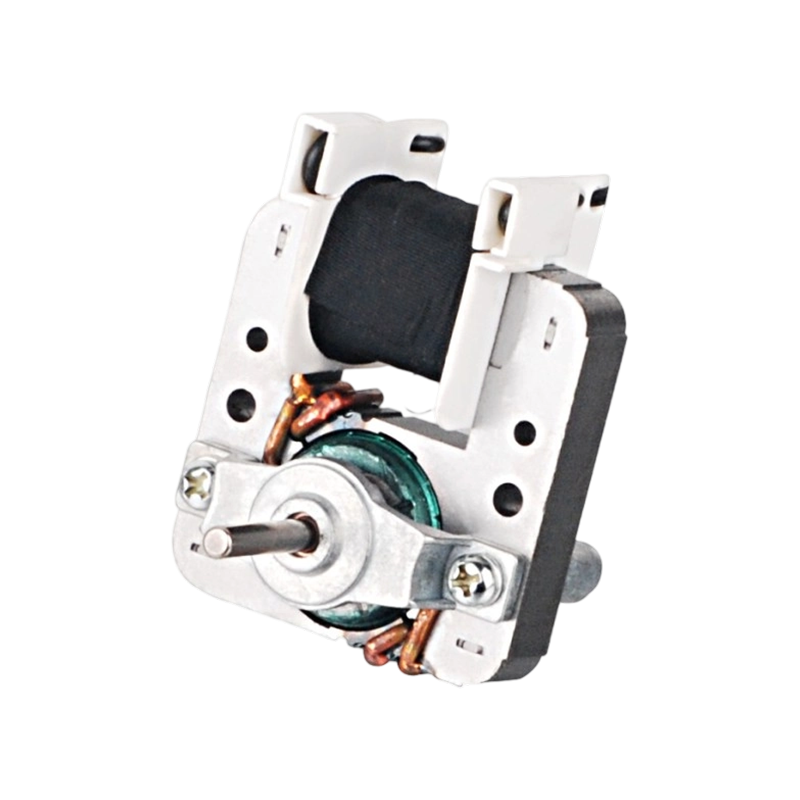

FJD-02 low noise motor for household appliances

Built for broad compatibility, this spare part operates seamlessly across 110-127V and 220-240V volt...

View More

FJD-02 low noise motor for household appliances

Built for broad compatibility, this spare part operates seamlessly across 110-127V and 220-240V volt...

View More

FJD-03small AC motor for fan or cooler

This appliance spare part features dual voltage support for 110-127V and 220-240V, along with 50/60H...

View More

FJD-03small AC motor for fan or cooler

This appliance spare part features dual voltage support for 110-127V and 220-240V, along with 50/60H...

View More

FJD-04 best electric motor for industrial use

Designed to fit a wide range of home appliances, this spare part supports both 110-127V and 220-240V...

View More

FJD-04 best electric motor for industrial use

Designed to fit a wide range of home appliances, this spare part supports both 110-127V and 220-240V...

View More

FJD-05 AC induction motor factory direct price

This home appliance spare part offers universal voltage support, working with 110-127V and 220-240V,...

View More

FJD-05 AC induction motor factory direct price

This home appliance spare part offers universal voltage support, working with 110-127V and 220-240V,...

View More

FJD-01B fan motor

With support for 110-127V and 220-240V voltages and 50/60Hz frequencies, this spare part is engineer...

View More

FJD-01B fan motor

With support for 110-127V and 220-240V voltages and 50/60Hz frequencies, this spare part is engineer...

English

English 中文简体

中文简体